Real-World Impact: How 3D Design Shapes Industries

- Home

- Real-World Impact: How 3D Design Shapes Industries

Real-World Impact: How 3D Design Shapes Industries

- Natcharat Kanwit

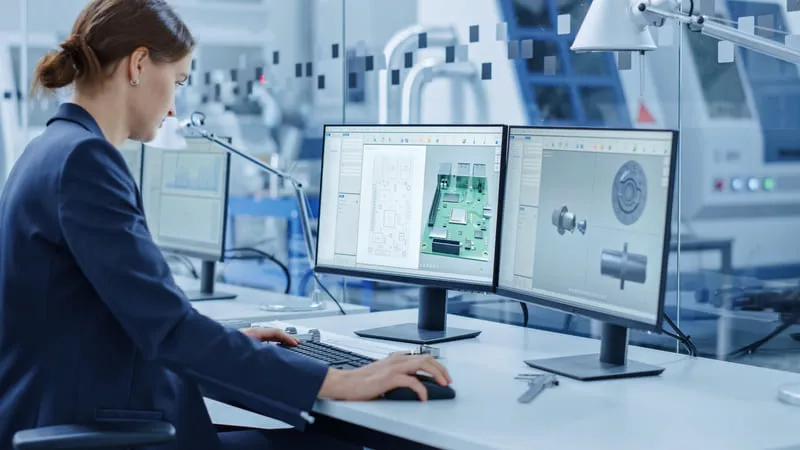

In today's industrial landscape, businesses constantly seek avenues for accelerated innovation and efficiency. Traditional design methods, relying on flat 2D blueprints and costly physical prototypes, often fall short. This conventional approach leads to prolonged development cycles, significant waste, and a lack of precise spatial understanding, hindering progress and market responsiveness.

The challenges extend beyond mere visualization. Iterative design processes, when tied to physical model creation, become prohibitively expensive and time-consuming. Each modification demands a new prototype, delaying crucial feedback and pushing back product launch dates. This sluggish pace impacts a company's ability to adapt to evolving market demands and stay competitive.

Furthermore, complex engineering and architectural projects demand unparalleled precision and clarity. Misinterpretations from two-dimensional representations can lead to costly errors during manufacturing. Inability to fully immerse stakeholders in a design often results in unexpected issues, rework, and budget overruns, eroding profitability and project timelines.

The symptoms are clear: missed deadlines, escalating development costs, and a struggle to bring innovative products to market swiftly. Industries from automotive to healthcare face immense pressure to deliver customized, high-quality solutions with speed. Without a fundamental shift, organizations risk falling behind, unable to meet modern demands for agility.

Root Causes of Design Inefficiencies

- Limited Visualization: 2D drawings often cause misinterpretations, leading to costly errors and project delays. True spatial understanding is often lost, impacting design accuracy.

- Expensive Physical Prototyping: Reliance on physical models for testing is costly in time and materials. Each iteration slows development and consumes budgets unnecessarily.

- Fragmented Collaboration: Disconnected tools hinder teamwork. This creates communication gaps, duplicates efforts, and impedes rapid decision-making across dispersed teams.

Transformative Solutions Through Advanced 3D Design

1. Accelerated Product Development and Virtual Prototyping

Modern 3D design software enables rapid conceptualization and refinement in a virtual environment. This greatly reduces the need for physical prototypes, allowing teams to test multiple variations digitally. Engineers simulate real-world conditions, identify flaws, and optimize designs before production, leading to faster time-to-market. Aetherbytezni empowers businesses in this transition.

By moving prototyping to the digital realm, companies gain agility. Designers experiment with forms and functionalities, receiving instant feedback. This iterative process, once a bottleneck, now drives innovation, enabling swift responses to market shifts with meticulously crafted products.

2. Immersive Training and Simulation Environments

Beyond product creation, 3D design revolutionizes workforce training and complex operation simulations. Realistic virtual environments allow employees to practice intricate procedures, operate machinery, or respond to emergencies without physical risk or equipment downtime. This provides a safe, controlled, and repeatable learning experience, enhancing skill acquisition.

For industries like healthcare and aviation, simulating critical operations offers immense value. Surgeons practice complex procedures, pilots train for conditions, and factory workers learn new assembly lines within a digital twin. This enhances skill retention and reduces human error in high-stakes situations.

3. Enabling Precision Manufacturing and Customization

The precision inherent in 3D design models translates directly into superior manufacturing outcomes. Providing detailed digital blueprints, 3D design facilitates advanced techniques like additive manufacturing and CNC machining. This enables production of complex geometries with extreme accuracy, opening doors for mass customization and on-demand production.

Companies can now offer products tailored to individual customer specifications without prohibitive costs or extensive lead times. From personalized medical devices to bespoke consumer goods, 3D design makes it feasible to produce unique items efficiently. This enhances customer satisfaction and minimizes waste, fostering a more sustainable supply chain, a core focus for Aetherbytezni.

Potential Risks and Mitigation Strategies

- Significant Initial Investment: Implementing 3D design infrastructure requires upfront capital. Recommendation: Opt for phased implementation or cloud-based SaaS to reduce initial costs and scale resources.

- Steep Learning Curve: Adopting new 3D design tools involves a significant learning curve for staff. Recommendation: Invest in comprehensive training and ongoing support for smoother skill development.

- Data Security Concerns: Storing proprietary 3D design files digitally raises IP protection questions. Recommendation: Implement robust encryption, secure cloud storage, and strict access controls.

Aetherbytezni

Aetherbytezni

Comments 0